Details of 6 inch Continuous-slot Well Screen

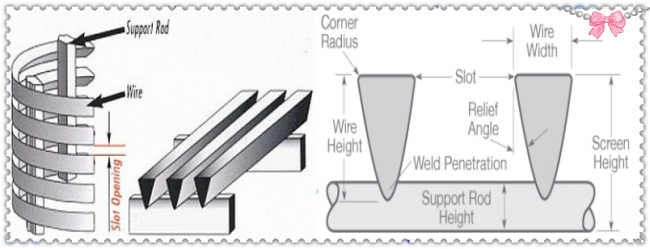

V wire screen profile

V wire Screens consist of V-shape profile wire and the longitudinal support rods.the wire is welded to the rods and produces a rigid unit that has high strength and minimum weight.

Specification of Continuous-slot Well Screen,

|

SIZE (inch) |

O.D (mm) |

SLOT (inch) |

LENGTH (m) |

Collapse Strength (psi) |

Tensile Weight (ton) |

Wire size (mm) |

RODS (mm) |

|

4 |

117 |

0.040 |

3 |

395 |

6 |

2.2*3.0 |

3.8mm/22 |

|

4 |

114.3 |

0.040 |

3 |

395 |

6 |

2.3*3.0 |

3.8mm/22 |

|

6 |

168.3 |

0.040 |

3 |

252 |

8 |

2.3*3.5 |

3.8mm/32 |

|

8 |

219.1 |

0.010 |

3 |

399 |

10.5 |

3.0*5.0 |

3.8mm/48 |

|

8 |

219.1 |

0.020 |

3 |

370 |

10.5 |

3.0*5.0 |

3.8mm/48 |

|

8 |

219.1 |

0.040 |

3 |

323 |

10.5 |

3.0*5.0 |

3.8mm/48 |

|

10 |

273.1 |

0.010 |

3 |

206 |

11 |

3.0*5.0 |

3.8mm/50 |

|

10 |

273.1 |

0.020 |

3 |

191 |

11 |

3.0*5.0 |

3.8mm/50 |

|

10 |

273.1 |

0.040 |

3 |

167 |

11 |

3.0*5.0 |

3.8mm/50 |

Technical patameter of 6 inch Continuous-slot Well Screen,

The V-shaped wire can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication if geologic conditions require these variations in a screen's construction.

|

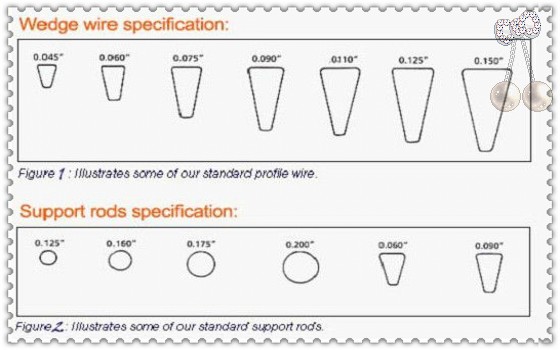

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size: |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length: |

up to 6 meters |

|

Diameter: |

6inch / 168mm |

Application of 6 inch Continuous-slot Well Screen

The continuous-slot well screen is recommended in the following situations;

Formation comprised of small or fine particles

Water wells where gravel packs will be installed

Thin aquifers, where maximum open area is required

Small diameter wells

The continuous-slot well screen is widely used throughout the world for water, oil, and gas wells, and is the dominant screen type used in the water well industry.